Kategorie: g_entkernen_grauguss_en

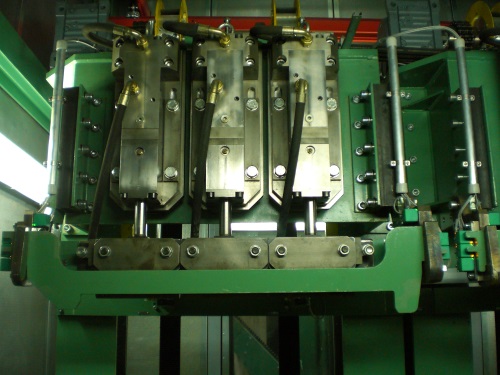

Decoring station for grey iron crankcases

This decoring station was designed under the aspects of high robustness and high casting flexibility.

The complete unit system is based on a shuttle-system which is in charge of the casting feed, -supply, -intake and discharge. When the casting has reached the decoring position it is pressed to the casting centering and the baffle plate by means of a lifting unit. The casting remains un-tensioned and can swing in eigenfrequency. So, adherent cores are broken effectively. When the decoring process is finished the casting is lowered again and driven out of the decoring station with the shuttle.

Technical data:

- Decoring station: two pieces with each three decoring hammers

- Decored casting types: crankcases

- Degree of automation: fully automated

- Loading/unlaoding: shuttle system

- Sand discharge: sand guiding plates and vibration conveyors