Kategorie: g_entkernen_aluminium_en

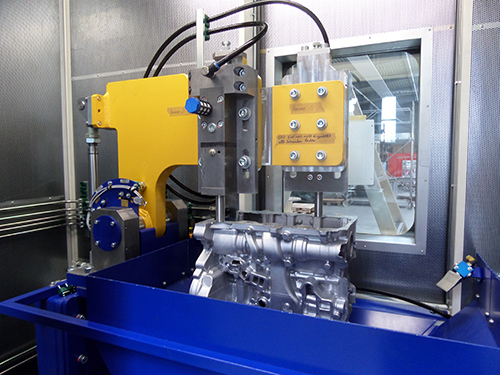

Post decoring station for crankcases

Especially in casting processes with inorganic binders in the core sand, problems with minimum residual sand may arise. In order to remove this residual sand for the most part, the R. Scheuchl GmbH has developed a special process. As to this, the casting is exposed to a special hammer process.

The reference example as shown here shows a post-decoring station which carries out the removal of residual sand. Due to noise prevention reasons the decoring station is encased in an individual sound insulating cabinet. Loading of the station is done by a robot by means of an L-sliding door. When the casting is inserted the hammer unit swivels pneumatically driven from the back over the crankcase. Then the decoring process is started automatically. When it is finished, the hammer unit swivels back and the robot can take out the crankcase from the station.

Technical data reference example:

- Types of castings: 4-cylinder crankcasese

- Oscillation movement: vertical

- Frequency: 33 Hz

- Hammer positioning: rotatable

- Number of hammers: two pieces

- Loading/unloading: robot

- Part clamping: not necessary

Technical data of post-decoring stations in general:

- Types of castings: crankcasese, cylinder heads, chassis parts, pump casings, etc.

- Oscillation movement: individually

- Frequency: 24 - 33 Hz

- Hammer position: fix, rotatable, moveable

- Max. casting dimension L/W/H: no limits

- Max. loading incl. holding fixture: no limits

- Piece clamping: not necessary

- Loading/unloading: manually or automated (robot)

- Integration on other stations: possible