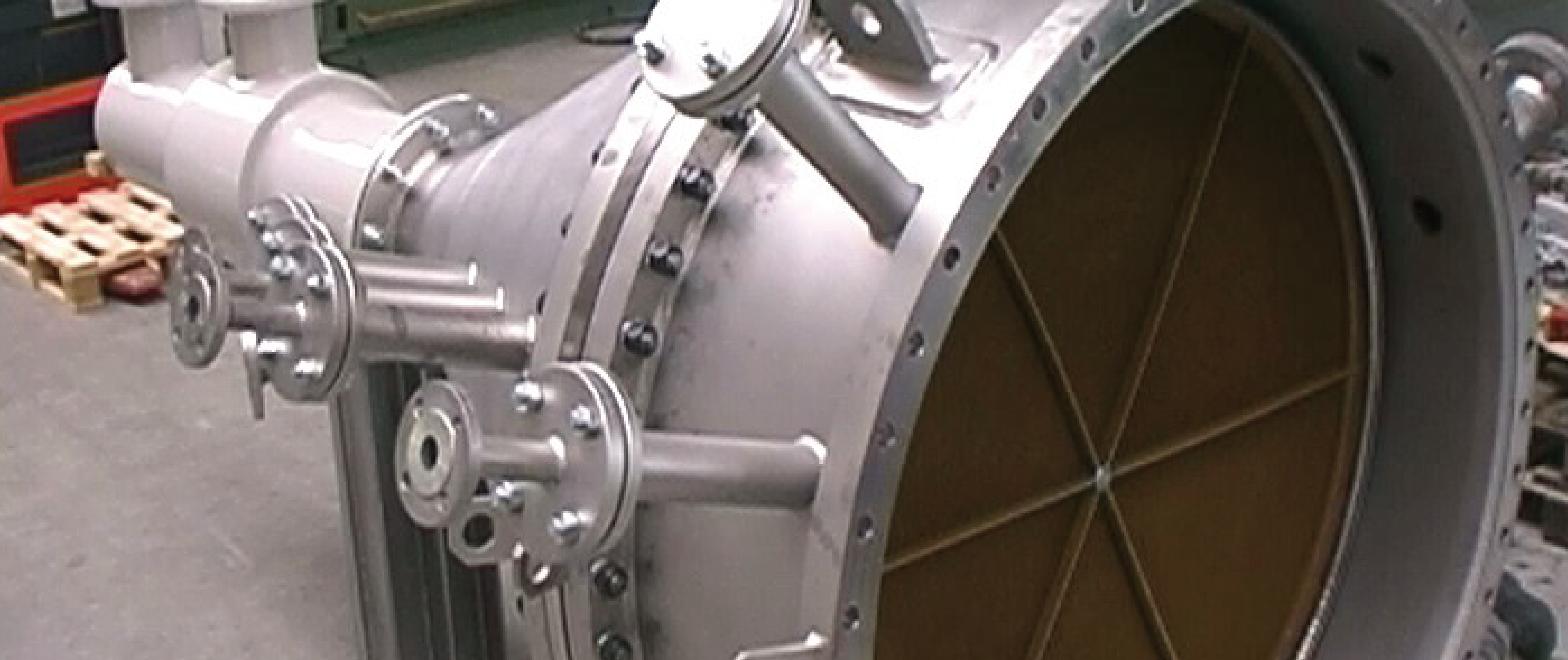

Catalytic oxidation systems

By catalytically assisted oxidation, VOCs can be completely oxidized already at a temperature of approx. 320°C. This makes it possible to clean waste air streams extremely energy-efficiently and save energy costs and CO2 compared to other thermal processes. The standard equipment for our catalytic oxidation systems includes either a natural gas burner or an electric air heater, making them extremely flexible to use. To recover the heat added to the process, an efficient heat exchanger is used. This enables autothermal operation of the plant from a pollutant concentration of approx. 3 gC/Nm³. Thus, ideally, no additional energy is required for VOC oxidation.

However, the catalyst must be protected from dust and so-called “catalyst poisons” to avoid premature deactivation of the cleaning performance. For this reason, a holistic analysis of the pollutants contained in the waste air is mandatory.

The process is based on reducing the activation energy for oxidation of the solvents by using a catalyst material, e.g., platinum or palladium.

Implemented applications:

- Almost all industrial sectors